Reverse Seat Metal Mesh

1. Technical Features & Innovation

-

Unique Weaving Method: The warp (longitudinal) wires are thicker with lower density, while the weft (transverse) wires are thinner with higher density. This "reverse" design ensures high strength and ultra-fine filtration performance.It can also be used as a belt-type continuous screen changer in fine filtration and extrusion processes in industries such as plastics, rubber, petroleum, chemicals, food, and pharmaceuticals.

-

Superior Material: Made of 316L stainless steel, offering resistance to acid, alkali, high temperatures (up to 800°C), and corrosion. Complies with German industrial standards (DIN/ISO) for long-term reliability .

-

Technical Breakthroughs:

-

High Weft Density Challenge: Solved wire breakage during weaving through upgraded CNC looms and optimized wire materials.

-

Surface Hardness: Enhanced heat treatment ensures hardness meets DIN 50133 standards (HV≥220).

-

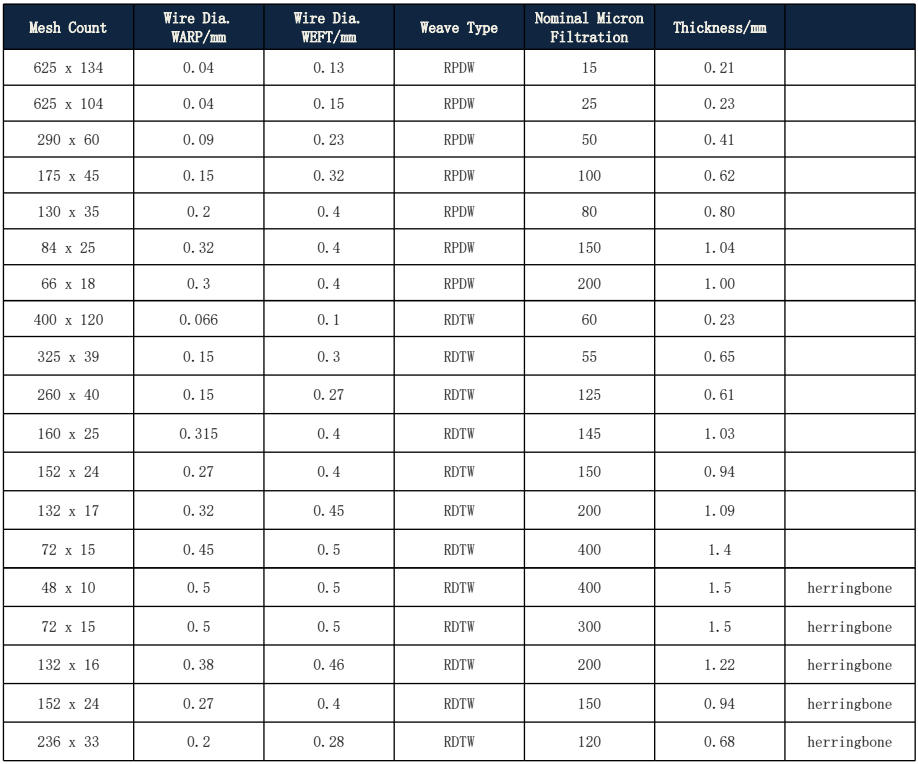

2. Product Specifications

Material stainless steel:302, 304, 316, 316L etc.

Standard Specifiction:

48x10 mesh RDPW 400 nominal micron

72x15 mesh RDTW 250 nominal micron

132x16 mesh RDTW 200 nominal micron

152x30 mesh RDTW 115 nominal micron

250x40 mesh RDTW 75 nominal micron

3. Applications

-

German Market Focus: Precision fuel filters, chemical reactors, pharmaceutical separation systems, and automotive exhaust filtration 29.

-

Certifications: RoHS-compliant, with third-party test reports (salt spray resistance >1,000 hours) 10.

4. Service & Support

-

Free Samples: Available for quality verification.

-

Factory Visit: Welcome to our facility in Anping, China (Asia’s largest wire mesh hub) for on-site audits.

-

Fast Delivery: 15-20 days for standard orders.